Cylinder Moulds

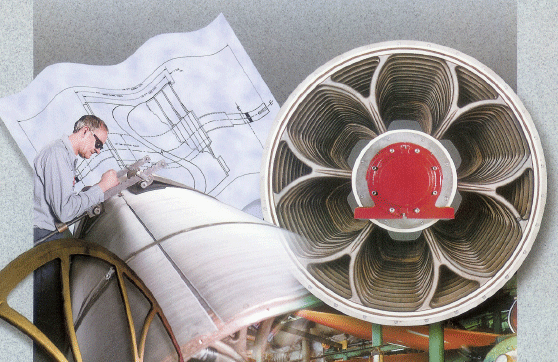

We employ proprietary manufacturing techniques and sound engineering principles to develop the best cylinder mould for your application. We work closely with you to determine the best cylinder design for your application and provide CAD and 3D visualization drawings for your review and approval prior to construction.

The Centrifugally Cast Core

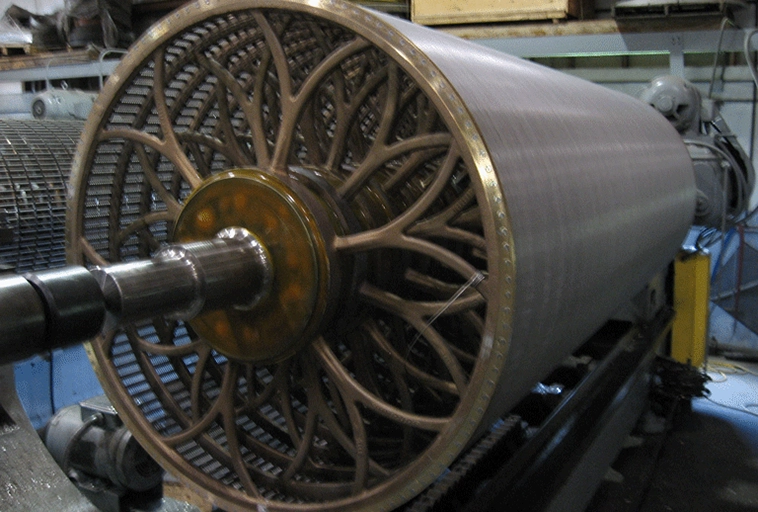

Our cylinders, with diameters ranging from 30” to 72”, begin with a hollow centrifugally cast iron core. Depending on application and budgetary restriction, a core clad with T-316L stainless sheet or a solid T-316L / T-304L center shaft may be used. Subjected to various wet environments, cast iron will not readily rust through and is considerably more corrosion resistant than steel.

Centrifugal casting produces a very dense core with excellent balance, rigidity, and walls of uniform thickness. Each core is engineered for maximum operating efficiency with minimum deflection. The core is shrink fit to each journal, then machined to uniform diameter to accept shrink fit spiders onto its shaft.

Our Cylinder Moulds are manufactured with either engineered cast bronze or stainless steel spiders. Bronze and T-316L has offered mills years of trouble free service at an economical cost. Engineered for strength, corrosion resistance and machined to precise tolerances, we are proud to say our spiders have consistently met or exceeded mill expectations for endurance and longevity over the years.

Johnston Dandy Cylinder Mould key features:

- High drawing efficiency

- Near perfect concentricity

- Maximum open area

- Ease of cleaning

- Minimum deflection due to a design which emphasizes stiffness and rigidity