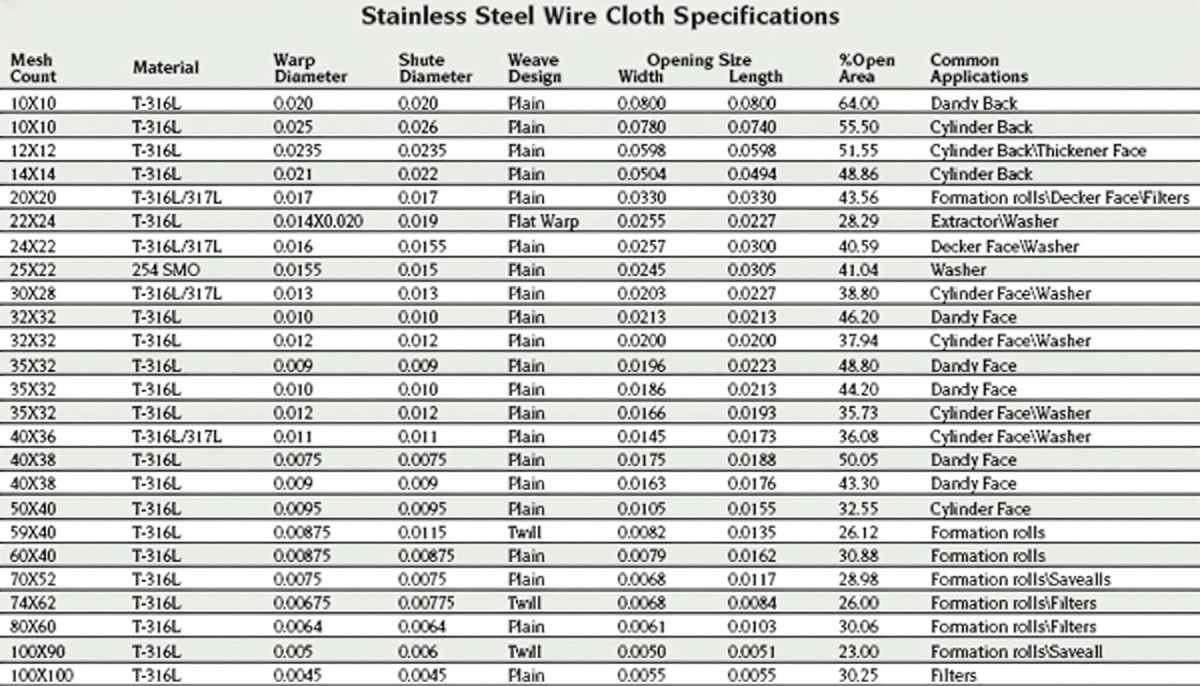

Wire Cloth

Manufacturing "Broad Loom" Metallic wire cloth for formation and filtration.

Pre-Seamed Sleeves, Cut Cloth, Belts

Pre-Seamed Sleeves

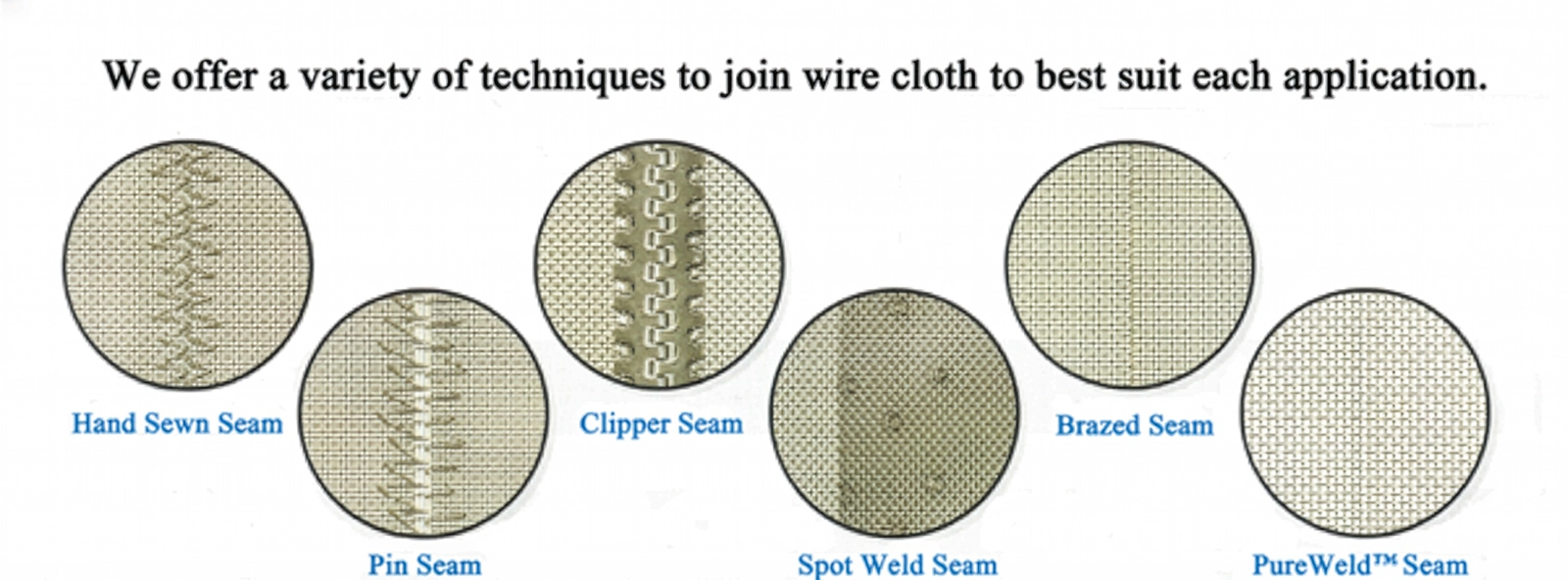

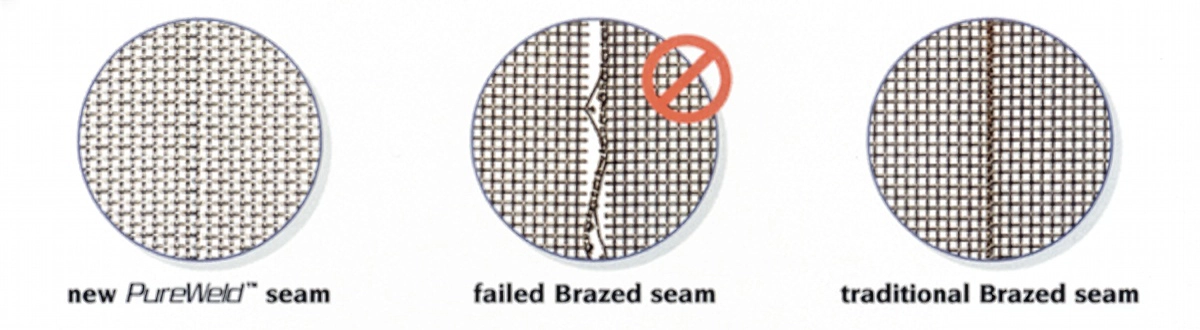

We have our master seamers create a sleeves that can suit an array of various applications. Whether you require brazed, bronze, or our specialized PureWeldtm seam we have the experience and expertise to deliver the longest lasting seams for your application.

Cut Cloth

We can cut any of our wire cloth to meet your specifications. Whether you are looking for small screens or large we can make a cut to suit your needs.

Belts

Whether you are running a drum or a long Fourdrinier table our wire can help you get the job done right. Using only the highest quality materials to create belts for superior formation of your product

PureWeld, Brazed, Spot & Pin Seams

Banding & Winding Wire

Banding:

We stock a large quantity of T-317 Stainless Steel and AL-6XN banding to meet all of your needs. Stock widths are 3/8", 1/2", and 5/8" wide and stock thicknesses are .020" and .030" for T-317 Stainless Steel and .030" thick for AL-6XN. Installation is available. Call for current pricing.

Winding Wire:

We stock a large quantity of T-316 Stainless Steel winding wire to serve the entire industry. A wide range of round, rectangular, and shaped winding. We also have limited stock of bronze winding as well as kynar rope. Installation is available. Call for current pricing.